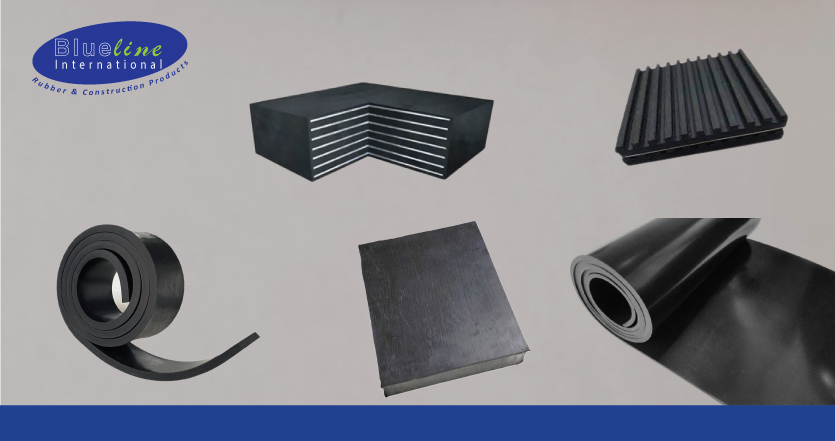

Neoprene Rubber Products

Neoprene rubber products play a vital role in the construction industry, offering exceptional durability, flexibility, and resistance to weather, UV rays, and chemicals. They are widely used in applications such as bearing pads for bridges and buildings, expansion joints, and sealing solutions for windows, doors, and waterproofing. Additionally, neoprene is ideal for anti-slip flooring, vibration dampening, and pipe gaskets. Its resilience under extreme conditions ensures long-lasting performance, making it a versatile solution for enhancing structural integrity and reliability in demanding environments.

Neoprene

Rubber Bearing Pad

Neoprene rubber bearing pads are essential components used in construction and infrastructure projects, particularly for bridges, buildings, and other heavy structures. These pads are designed to provide flexibility, durability, and shock absorption while distributing loads and minimizing vibrations. Here’s a detailed overview of neoprene rubber bearing pads:

Functionality

Neoprene rubber bearing pads are used primarily to:

- Distribute Loads: They evenly distribute the weight of the structure across the surface, reducing localized pressure and preventing damage to both the bearing surface and the structure.

- Shock Absorption: Neoprene’s elasticity allows it to absorb and dissipate shock and vibrations, which is particularly important for structures exposed to dynamic forces, such as traffic on bridges or machinery vibrations in buildings.

- Movement Accommodation: These pads allow for thermal expansion and contraction, as well as minor movements due to shifting or settling of the structure.

Applications

Neoprene rubber bearing pads are widely used in:

- Bridge Construction: They are placed between the bridge deck and the supporting structure to accommodate movement and distribute the weight of the deck.

- Building Foundations: In buildings, they are used to isolate the structure from ground movement or vibrations from nearby machinery or traffic.

- Heavy Equipment: They serve as shock absorbers in heavy machinery, providing a stable base while reducing wear and tear on both the equipment and the foundation.

Design and Customization

- Neoprene rubber bearing pads can be customized in terms of thickness, size, and shape to meet the specific needs of a project. They may also include reinforcing layers, such as steel shims, to enhance load-bearing capacity and durability. Additionally, neoprene bearing pads can be manufactured to meet specific industry standards, including those for seismic or thermal movement applications.

Benefits

- Durability: Neoprene is highly resistant to aging, UV radiation, and ozone, ensuring long-lasting performance.

- Versatility: Suitable for a wide range of temperatures and environmental conditions.

- Cost-Effective: Neoprene bearing pads are relatively affordable compared to other materials like steel or elastomeric bearings.

- Ease of Installation: These pads are lightweight and easy to install, making them a preferred choice for many engineers.

Neoprene

Rubber Sheet

Neoprene rubber sheets are indispensable in the construction industry due to their exceptional durability, adaptability, and resistance to environmental factors. From sealing and waterproofing to vibration dampening and protective linings, these sheets provide reliable solutions for a wide range of construction applications, ensuring structural integrity and long-term performance.

Neoprene rubber sheets are versatile and widely used in the construction industry due to their excellent mechanical properties, durability, and resistance to environmental factors. These sheets are manufactured from polychloroprene, a synthetic rubber known for its superior performance in demanding applications.

Key Properties of Neoprene Rubber Sheets

- Durability: Neoprene sheets exhibit high tensile strength and resistance to wear and tear, making them ideal for heavy-duty applications.

- Weather Resistance: They are highly resistant to UV radiation, ozone, and weathering, ensuring long-term performance in outdoor environments.

- Chemical Resistance: Neoprene resists a wide range of chemicals, oils, and fuels, making it suitable for use in industrial and construction settings.

- Thermal Stability: With a broad operating temperature range (-40°C to 120°C), neoprene sheets perform well in both hot and cold climates.

- Flexibility: These sheets maintain flexibility under stress, allowing them to adapt to structural movements and irregular surfaces.

- Waterproofing: Neoprene’s impermeability to water makes it an excellent choice for sealing and waterproofing applications.

Applications in the Construction Industry

- Expansion Joints: Neoprene sheets are used as expansion joint fillers to accommodate thermal expansion and contraction in structures like bridges, buildings, and pavements.

- Sealing and Gaskets: They serve as seals and gaskets in construction projects to prevent leakage of air, water, or chemicals.

- Vibration and Sound Dampening: Neoprene sheets are used to reduce noise and vibration in building foundations, machinery bases, and HVAC systems.

- Roofing and Waterproofing: They act as a waterproof layer in roofing systems, protecting structures from water infiltration.

- Flooring and Anti-Slip Mats: Neoprene sheets provide a durable, non-slip surface in areas prone to heavy foot traffic or equipment movement.

- Protective Linings: They are used as protective linings for walls, floors, and other surfaces exposed to abrasive or corrosive conditions.

Advantages of Neoprene Rubber Sheets in Construction

- Longevity: Neoprene sheets have a long service life, reducing the need for frequent replacements.

- Versatility: Available in various thicknesses, sizes, and hardness levels to meet specific project requirements.

- Ease of Installation: Lightweight and easy to cut, shape, and install on-site.

- Eco-Friendly Options: Some neoprene sheets are manufactured with environmentally friendly processes and materials.

Customization and Standards

- Neoprene rubber sheets can be customized to meet specific construction standards, including fire resistance, load-bearing capacity, and thermal insulation requirements. They are often manufactured in compliance with international standards such as ASTM or ISO.

Neoprene

Anti-Vibration Pads

Anti-vibration pads are essential components in reducing noise, vibrations, and shocks in various applications. These pads are designed to isolate machinery and equipment from their supporting structures, preventing damage and improving operational efficiency. Ribbed and plain anti-vibration pads are two common types, each offering unique benefits depending on the application.

Ribbed Anti-Vibration Pads

Design and Features

- Ribbed Surface: These pads feature a grooved or ribbed pattern on one or both sides, enhancing their grip and stability.

- Material Composition: Typically made from high-grade rubber, such as neoprene or natural rubber, often combined with cork or other materials for additional damping.

- Load Distribution: The ribbed design helps evenly distribute the load, increasing the pad’s effectiveness in isolating vibrations.

Advantages

- Enhanced Grip: The ribbed surface provides better friction, preventing slippage under heavy loads or dynamic conditions.

- Improved Air Circulation: The grooves allow air circulation, which can help in heat dissipation during operation.

- Versatility: Suitable for a wide range of applications, including industrial machinery, HVAC systems, and heavy equipment.

Applications

- Heavy-duty machinery in manufacturing plants.

- HVAC units, compressors, and generators.

- Precision equipment where stability and vibration control are critical.

Plain Anti-Vibration Pads

Design and Features

- Smooth Surface: These pads have a flat, even surface, offering a uniform base for equipment.

- Material Composition: Made from durable rubber or elastomeric materials, sometimes reinforced with fabric or metal for additional strength.

- Load-Bearing Capability: The plain design ensures even load distribution, making them suitable for static applications.

Advantages

- Ease of Installation: The flat surface simplifies placement and alignment.

- Cost-Effective: Generally more affordable than ribbed pads due to simpler manufacturing processes.

- Broad Compatibility: Ideal for lighter equipment or applications where grip is less critical.

Applications

- Office equipment like printers and copiers.

- Small to medium-sized machinery.

- Residential or commercial HVAC units.

Material Options

Both ribbed and plain anti-vibration pads are available in various materials to suit specific requirements:

- Neoprene: Resistant to oil, grease, and weathering.

- Natural Rubber: Excellent elasticity and vibration damping.

- Cork-Rubber Composite: Combines the damping properties of cork with the durability of rubber.

Benefits of Anti-Vibration Pads

- Reduced Noise and Vibrations: Improves workplace comfort and equipment efficiency.

- Extended Equipment Life: Minimizes wear and tear caused by vibrations.

- Easy Maintenance: Simple to install and replace when needed.

- Safety: Prevents equipment movement, reducing the risk of accidents.

Other Products

- Acoustic Sound Insulation PU Foam Sheet Board

- Compressible Filler Board

- Dimple Sheets: Advanced Drainage and Protection Solutions

- Drain Cell Tank: Modular Water Management Solution

- Drain Cells: Advanced Drainage and Water Management Systems

- EPDM Rubber Profiles

- Geotextiles

- HDPE Geomembranes

- HDPE Microducts

- HDPE Sand-Coated Waterproofing Membrane

- NBR Foam Sheets

- Neoprene Rubber Products

- Parking Rubber Products & Accessories

- PVC and TPE Profiles

- Rubber Acoustic Underlay

- Silicone Rubber Profiles

- U-Bolt with Rubber Sleeve / Grip